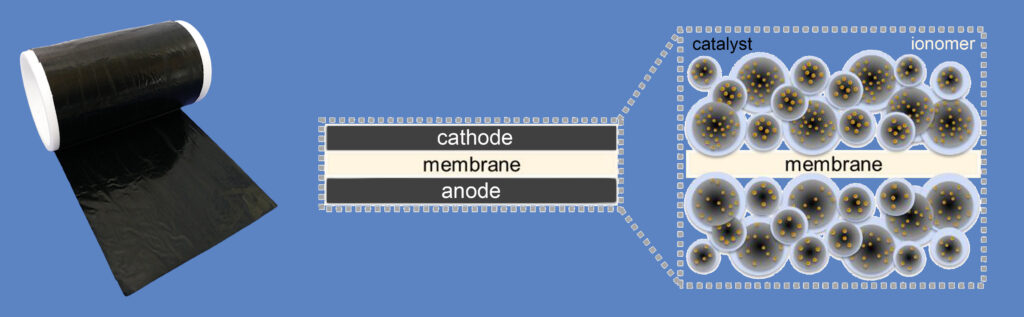

PEM fuel cells convert hydrogen and oxygen into water and release energy in the process. The heart of a fuel cell is a proton exchange membrane (PEM) which is coated on both sides with a cathode and an anode catalyst layer: catalyst-coated membrane (CCM).

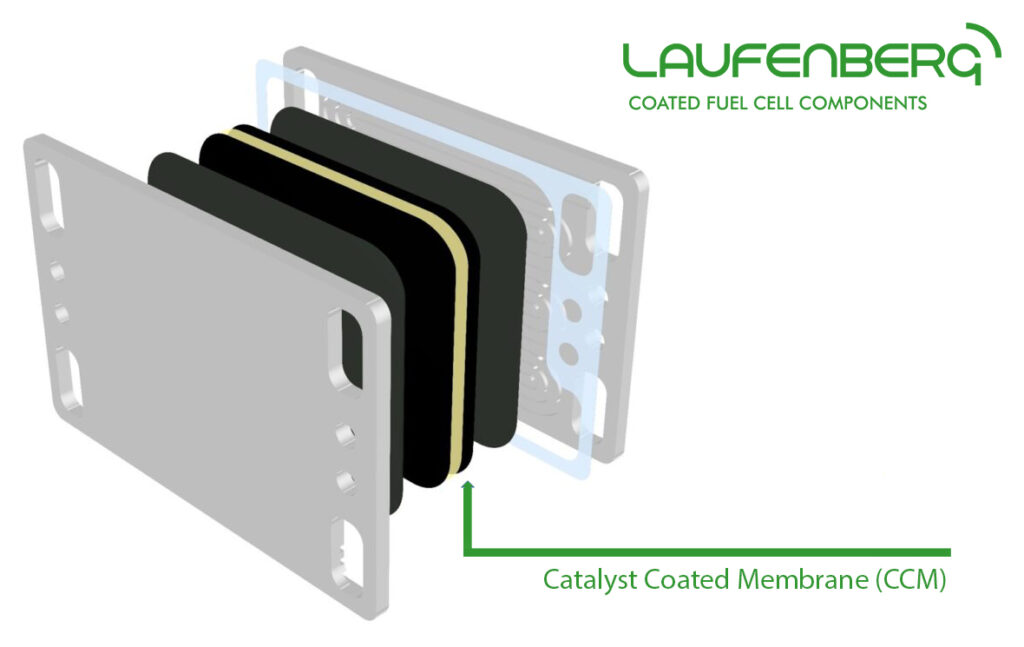

Together with other components, the catalyst-coated membrane (CCM) is assembled to form the membrane electrode assembly (MEA), which is needed in a PEM fuel cell to convert chemical energy into electrical energy.

Catalyst coated membrane (CCM)

Laufenberg’s Catalyst Coated Membrane (CCM) is designed to make the power generation process as powerful and age-stable as possible. The CCM consists of a cation exchange membrane coated with a cathode and an anode catalyst layer. We produce our CCM’s at our production site in Krefeld, Germany.

Technical Data Sheet Catalyst Coated Membrane (CCM)

Your requirements on the material

In CCM production, we are guided entirely by your requirements for the material.

✔ We are also happy to offer you a Laufenberg standard for automotive or heavy-duty applications.

✔ Through our project-based contract manufacturing, it is possible for us to vary the carrier membrane as well as the catalytic converter for you.

✔ We have fully equipped laboratories and a pilot plant to find the perfect solution for your needs.

✔ Through our production process, we manufacture the CCM as roll goods. This makes the product particularly suitable for series production. On request, the CCM can also be obtained as format goods.

✔ Even though our capacities are designed for larger order quantities, you can also order small production batches from us.

Feel free to contact us. Together with our R&D department and the available pilot plant, we will accompany you on the way from laboratory scale to roll-to-roll production.

You can find information about our pilot plant here.

Dr. Sebastian Kohsakowski

+49 (0)2151 74 99 551

s.kohsakowski@laufenberg.info

Contact