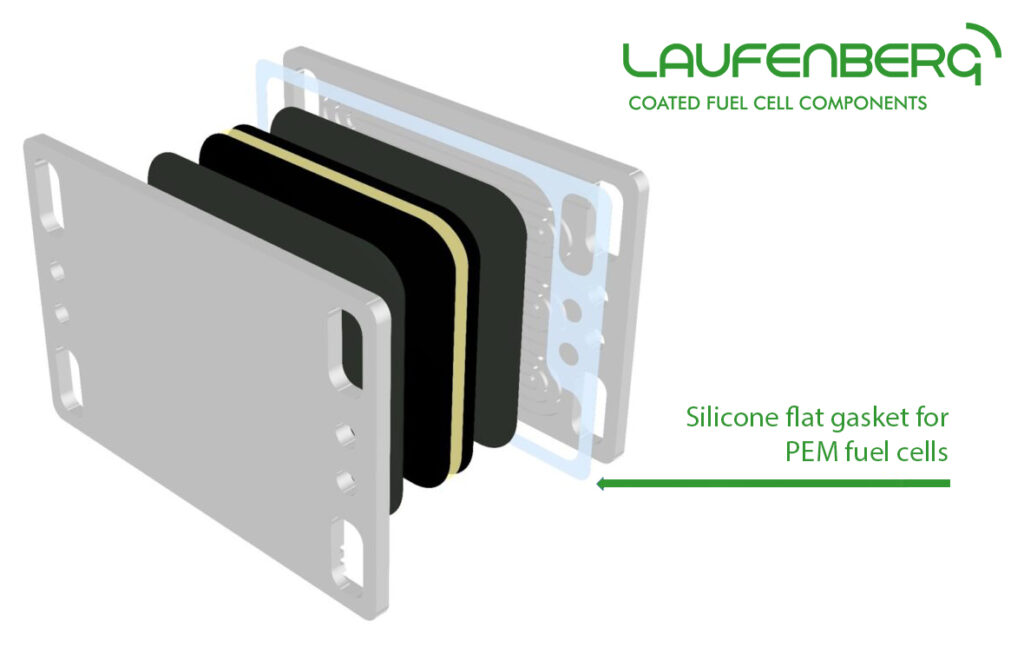

As an important component of the fuel cell, the silicone flat gasket serves both to seal the cells between the membrane and the bipolar plate and to provide water cooling during stack assembly.

Silicone flat gasket for PEM fuel cells

Our silicone flat gasket with PET core was developed in years of cooperation with research institutes and customers especially for use in PEM fuel cells. Our goal was to be able to offer the growing fuel cell market high-quality gaskets efficiently and economically in the long term.

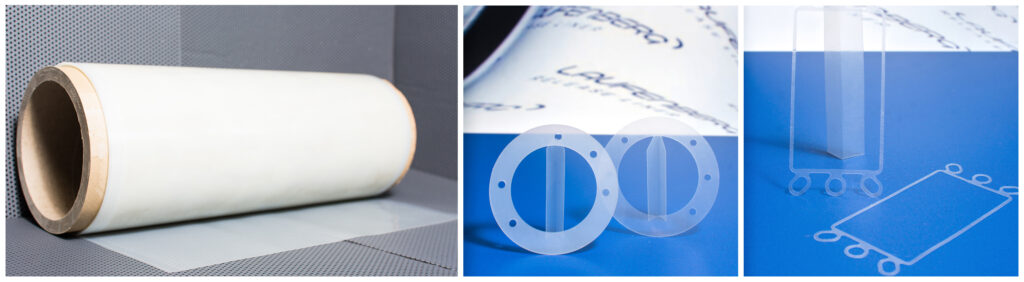

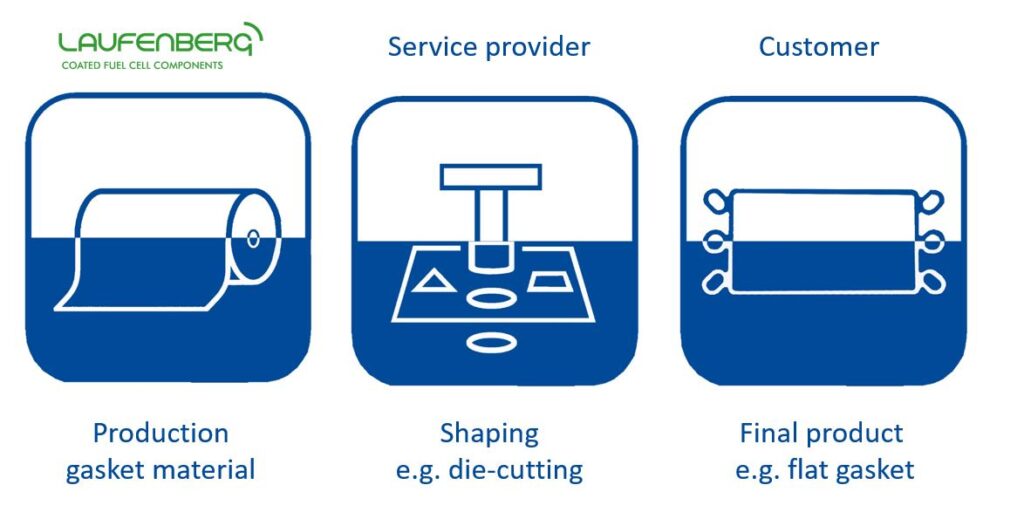

Roll material by Laufenberg Final externally die-cut products

Features

- Good compressibility

- High tightness

- Low surface roughness

- Good positionability due to rigidity (quick assembly) & dimensional stability

Compared to other pure silicone flat gaskets available on the market, our material is characterised by its dimensional stability and the resulting optimal positioning during stack assembly.

In addition, the roughness of the surface is very low due to our manufacturing process. Due to the very even surface profile, a high gas and water tightness of the cell is already achieved with a low contact pressure. This eliminates the need for additional gluing of the seal.

The material can be produced in almost any desired thickness. Currently, thicknesses of 200 – 700 µm are commercially available. A low thickness tolerance of a few µm can be achieved during production.

Technical data sheet silicone flat gasket for PEM fuel cells (PDF)

Production process

Your requirements on the material

We manufacture our silicone flat gasket entirely according to your material requirements.

✔ Our silicone gasket with PET core is available in different thicknesses. The product can be obtained as a single-sided or double-sided coated version.

✔ Depending on the customer’s panel design, the optimum coating thickness can be produced to within a few µm of the desired thickness.

✔ We produce our product in rolls for your series production. On request, we can also offer the material as formats.

✔ Fabrication is basically possible with laser or water jet and with commercially available punching knives.

✔ For test purposes, we offer DIN-A4 samples of our standard layer thicknesses. By agreement, we also offer test productions for a fee from as little as one square metre.

✔ The material can also be used for other applications (e.g. electrolysis sector, e-bike sector, etc.).

Dr. Sebastian Kohsakowski

+49 (0)2151 74 99 551

s.kohsakowski@laufenberg.info

Contact