Climate protection cannot wait: discover our new business field

Fuel cell technology is considered the efficiency technology of the future. The idea behind them is already more than 180 years old: hydrogen plus oxygen generate electricity and heat. Fuel cells operate completely emission-free: the only waste product is water in vapour and liquid form.

The conversion of the water and atmospheric oxygen into electrical energy takes place in a stack, a stack of fuel cells connected in series. In recent years, there has been an intensive search for innovative and qualitative manufacturing processes for the individual components of the fuel cell.

To take account of this development, we have been active in the field of fuel cell and hydrogen applications since 2014. Together with research and industry partners, we develop innovative components for fuel cells based on our own coating technology. Our goal is to meet the world’s growing energy demand and environmental concerns.

Using synergies

Laufenberg has over 75 years of experience in coating technology from its main business with release liners. We stand for the best solutions based on silicone-coated films and papers as well as special products. Our expert knowledge, many years of experience, state-of-the-art machinery and our high standards of service and quality provide the perfect prerequisites for our “coated fuel cell components” business segment.

This is where all available synergies come together and flow into the development of innovative products.

Our products

We have already successfully launched the following fuel cell components on the market:

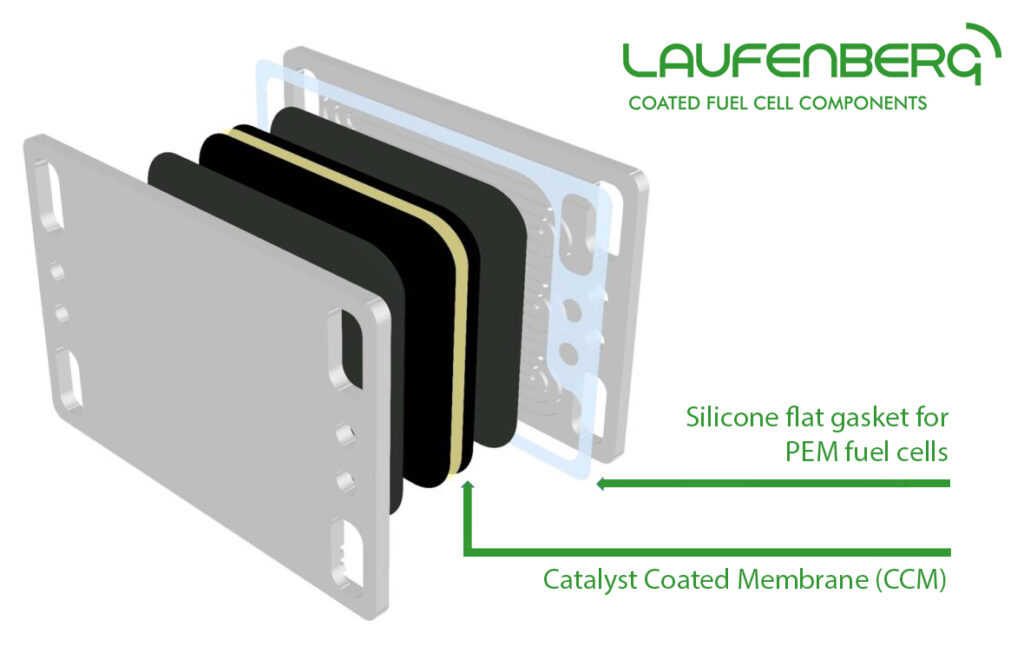

Catalyst Coated Membrane (CCM)

✔ Special thermal conductive coating for improved performance of conventional electrical insulation papers

✔ Individually adjustable precious metal content

✔ As roll or format goods for series production

✔ Customized & Made in Germany

Silicone flat gaskets for PEM fuel cells

✔ Extremely tight and with improved stability

✔ Optimal positionability and processing

✔ Reduced roughness and even surface profile with excellent adhesion

Both products are available as format goods or as more cost-effective roll goods for your series production. Thanks to our own coating technology, the special coatings can be applied to different substrates, depending on the customer’s requirements. The thickness of the coating and thus the thickness of the overall product can be varied.

Contact us, we will be happy to personally present our range of processes, new materials and solutions in the field of fuel cell components.

Dr. Sebastian Kohsakowski

+49 (0)2151 74 99 551

s.kohsakowski@laufenberg.info

Contact